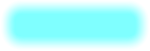

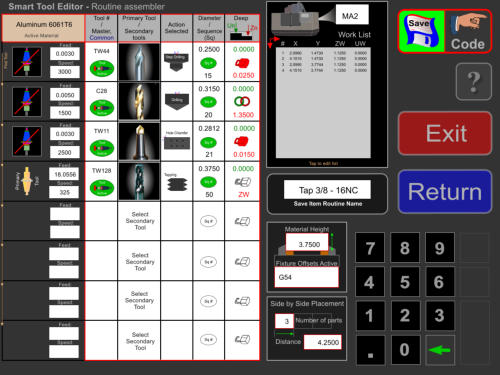

Smart Tools - Tapping without writing code

Use your CNC machine in lieu of a manual machine for small jobs. Select a tool - Enter coordinates - Run it.

Select and execute a single

tool or assemble a routine for

the selected “Primary Tool”.

Just enter the coordinates

and click “Next”. (leave the

coordinate X,Y fields empty and

the routine is executed from the

current spindle position. This

feature makes it possible to use

your CNC mill like a manual

machine)

Tools that are not in the

machine will be installed,

Offsets uploaded and the

generated Code is transfered

to the machine.

Save the routine and recall at

any time. Once built, they

become a “Time Saving”

asset.

No programming knowledge

required!

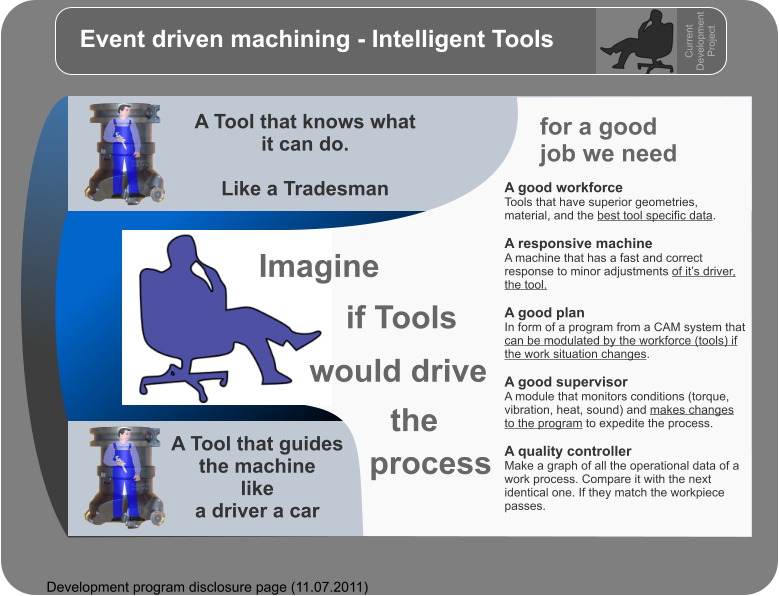

Our Goal

Note: Analyzing and programming for each tool or tool group is a tall order and requires a lot of time. We will therefore release the

Smart Tool package not as one module but enable various tool or tool groups within the software as they become available.

The “Smart Tool” Tapping function is in the testing phase

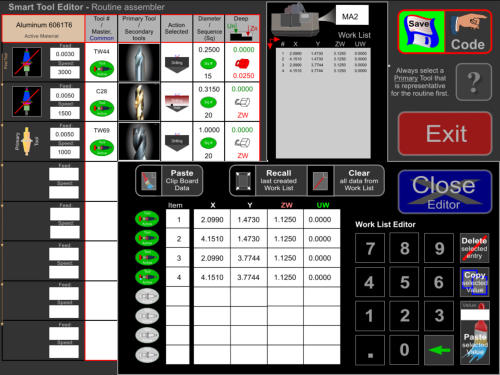

Single / Multi Tool Conversational Machining

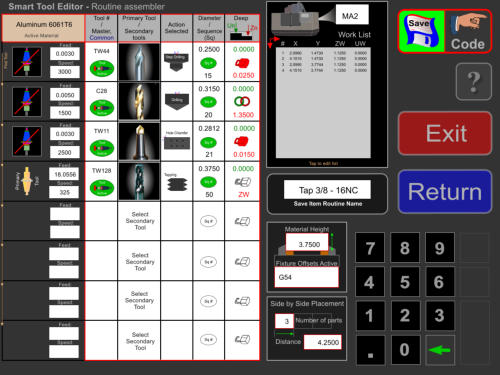

Smart Tools - CB without writing code

Counter Bore as a single tool action by selecting the Primary Tool from Tool Wall.

How to do it:

1) Select the Primary Step

Drill (Counter Bore Drill) from

the tool changer of a machine.

3) Enter the X,Y,Z coordinates

or only the Z coordinate to

execute from the current

position.(this feature makes it

possible to use your CNC mill like a

manual machine)

4) Confirm the fixture and

Work offsets from list.

Click Next: The code is sent to

the machine for you to start

working.

Note: Unless a saved routine

is called, the Primary Tool has

to be installed in a machine.

All other tools will be installed

automatically if not present.

Note: Analyzing and programming for each tool or tool group is a tall order and requires a lot of time. We will therefore release the

Smart Tool package not as one module but enable various tool or tool groups within the software as they become available.

Single / Multi Tool Conversational Machining

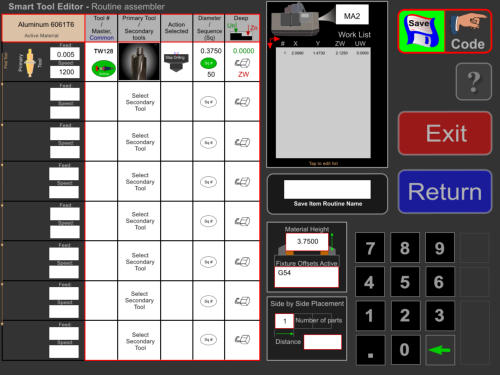

Smart Tools - Drill & CB without writing code

Dill a hole and Counter Bore can be combined into a routine. Make drill pattern and save as a file for recall.

How to do it:

1) Select the Primary Step

Drill (Counter Bore Drill) from

Tool Wall.

2) Browse and select a routine

from the Routine List

3) Enter the X,Y,Z coordinates

or only the Z coordinate to

execute from the current

position.(this feature makes it

possible to use your CNC mill like a

manual machine)

4) Confirm the fixture and

Work offsets from list.

Click Next: The code is sent to

the machine for you to start

working.

Note: Tools that are not in the

machine will be installed

automatically.

Note: Analyzing and programming for each tool or tool group is a tall order and requires a lot of time. We will therefore release the

Smart Tool package not as one module but enable various tool or tool groups within the software as they become available.

Single / Multi Tool Conversational Machining

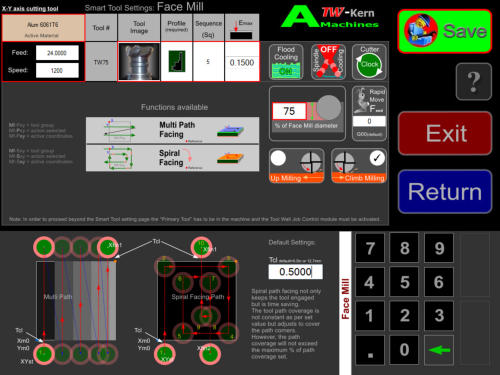

Smart Tools - Face-mill settings page

The “Face-mill” is mostly used

in a separate operation such

as work piece preparation or

finishing.

Before any Smart Tool can be

used, the corresponding tool

settings have to be applied

which become the default after

completion.

The input however is minimal

as most settings are defaulted

from the tool profile and/or

from previous values applied.

The “Face-mill Action” is supported by two tool functions. Shown is the face-mill tool settings page.

The “Smart Tool” Face Mill is available now

Note: Analyzing and programming for each tool or tool group is a tall order and requires a lot of time. We will therefore release the

Smart Tool package not as one module but enable various tool or tool groups within the software as they become available.

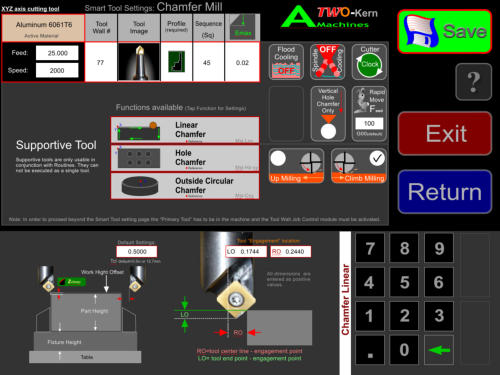

Smart Tools - Chamfer tool settings page

The “Chamfer Action” is supported by three tool functions. Shown is the chamfer tool settings page.

The “Chamfer Tool” is mostly

used as a “Secondary Tool”,

a supporting role of other

“Primary Tool” routines.

The correct function is

therefore selected

automatically from within the

selected routine.

Note: Analyzing and programming for each tool or tool group is a tall order and requires a lot of time. We will therefore release the

Smart Tool package not as one module but enable various tool or tool groups within the software as they become available.

The “Smart Tool” Chamfer function is available for linear function

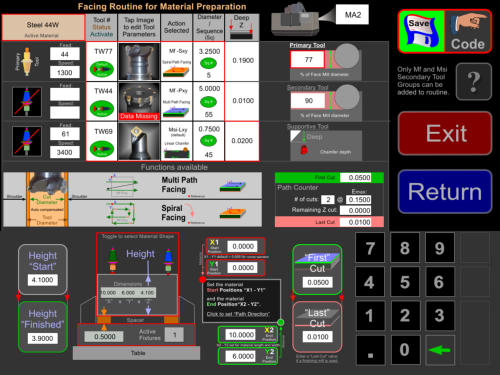

Smart Tools - Facing without writing code

The “Facing Function” is supported by two tool path pattern functions. Execute one tool, two tools, or all three.

How to do it:

1) Enter “Starting Thickness”

2) Enter “Finishing Thickness”

3) Choose if you want a

“First Cut” to take off mill-scale,

when milling steel.

4) Choose if you want a “Last

Cut” to have a good finish.

5) Enter “Work Piece”

coordinates.

6) Select “Multi Path” or “Spiral

Path” function.

7) Click “Next”.

(The code is transfered to the

machine for you to start milling)

Note: The Primary Tool has to be

installed in a machine. All other

tools will be installed

automatically if not present.

The “Smart Tool” Facing function is available now

Note: Analyzing and programming for each tool or tool group is a tall order and requires a lot of time. We will therefore release the

Smart Tool package not as one module but enable various tool or tool groups within the software as they become available.

Single / Multi Tool Conversational Machining

Smart Tools - Drilling large diameter holes

Just select a larger diameter drill

from a tool changer and it will

bring up the preset legend.

The protocol calls for a Center

Drill a Pre-Drill and the Primary

Tool.

The Pre-drill is set for drilling as

deep as the Primary Tool. If

however the set depth of the

Primary Drill is deeper then the

length of the Pre-Drill allows, the

pre-drilling is done only of the E-

max value of the Pre-Drill.

The work flow is simple:

1) Select the drill for the size of

hole you want to drill from the tool

changer.

2) Enter the X,Y,Z coordinates or

only the Z coordinate to execute

from the current position.(this

feature makes it possible to use your

CNC mill like a manual machine)

3) Click “Code” (the generated G-

Code is sent to the machine).

4) Execute (run) the program.

Note: Analyzing and programming for each tool or tool group is a tall order and requires a lot of

time. We will therefore release the Smart Tool package not as one module but enable various

tool or tool groups within the software as they become available.

Use your CNC machine in lieu of a manual machine for small jobs. Select a tool - Enter coordinates - Run it.

The “Smart Tool” Drilling function is in the testing phase

Single / Multi Tool Conversational Machining

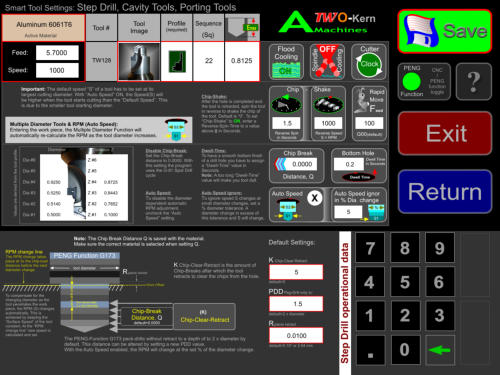

Smart Tools - PENG Function G173

Basic canned cycles are often

insufficient to control specialized

tools or the resulting chips.

Currently we are developing axis

specific functions for better tool

control and Macros for machining

standard objects.

Besides tapping, our P.E.N.G.

G173 function is used for all Z-

Axis movements and has the

flexibility to adjust to all tools. The

needed function variables are

entered automatically from the

TW tool data and are invoked by

selecting a tool from Tool Wall.

Depending on the tool selected,

G173 produces different results

with only one function.

The example on the left shows

the tool setting UI of a Porting

Tool. The PENG G173 Macro

function for this tool automatically

changes the RPM with a

diameter change, resulting in

optimal cycle time, carbide life,

chip control and surface finish.

Note: We invite tool manufacturers to participate in Smart Tools. Data of participants is resident in Tool Wall. This data is inserted as default

whenever a participants tool is used. Tools are operated with optimal tested manufacturer cutting data, reducing data related tool breakage.

Pre-Engineered Numeric G-code

Custom canned cycle

development program

disclosure (07.07.2015)

Note: Analyzing and programming for each tool or tool group is a tall order and requires a lot of time. We will therefore release the

Smart Tool package not as one module but enable various tool or tool groups within the software as they become available.