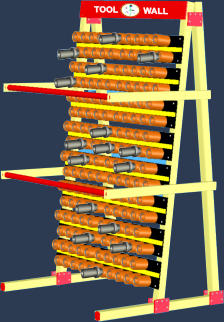

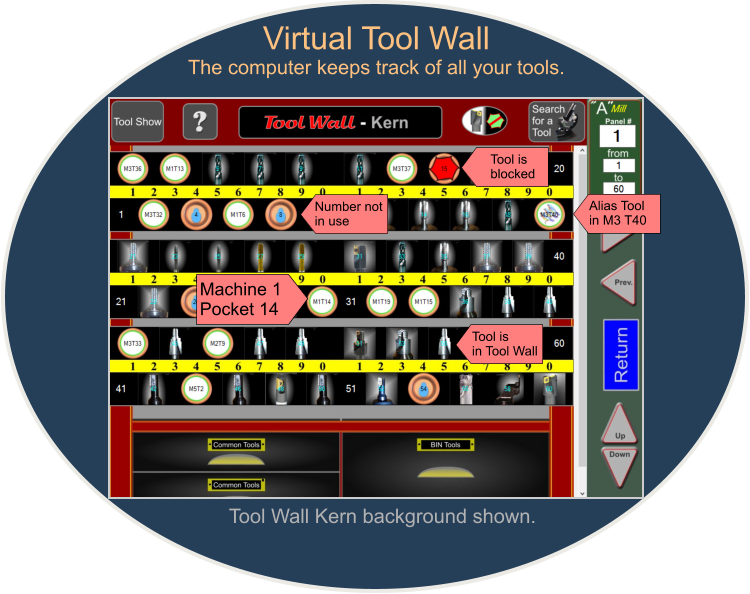

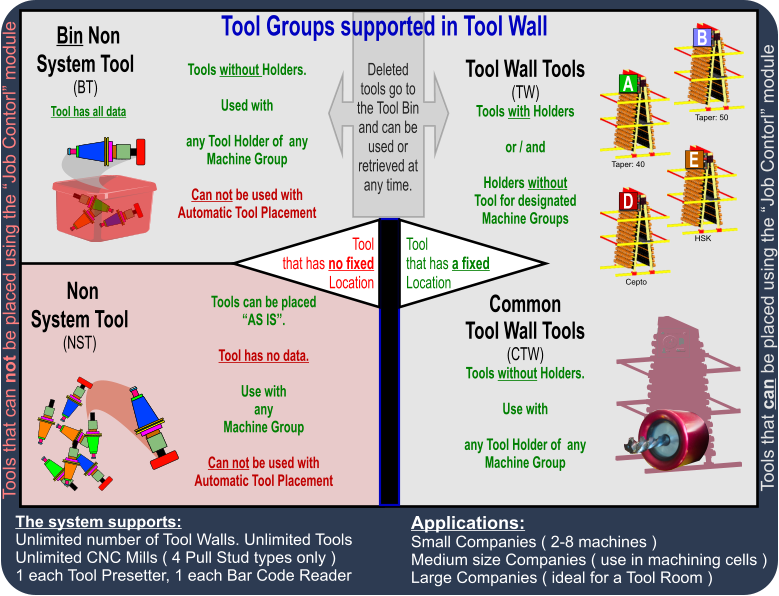

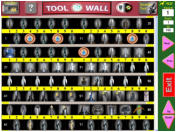

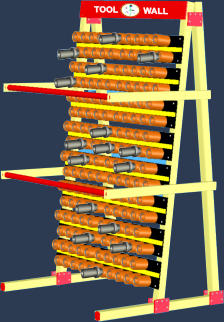

All Tool Wall tools

are pre-set for

instant deployment

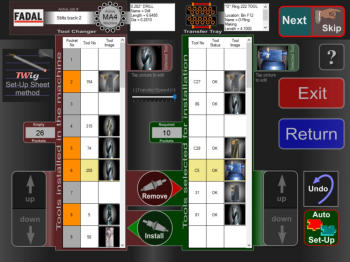

TWin

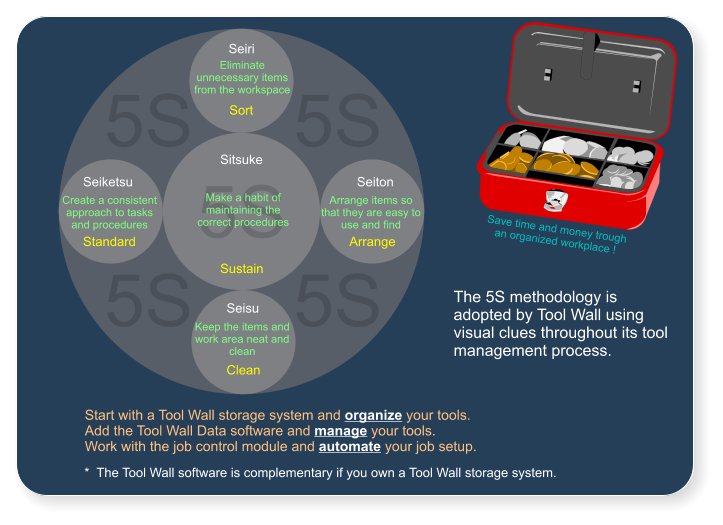

5S(methodology) tool handling system

5S from 5 Japanese words: seiri, seiton, seiso, seiketsu, shitsuke

5S is a system to reduce waste and optimize

productivity through maintaining an orderly

workplace and using visual clues to achieve more

consistent operational results where every tool

has a for everyone to find designated spot.

5S brings vast Productivity, Organisational, Neatness,

Standardisation and Safety improvements when implemented.

4 Set-Up Methods for you to choose from

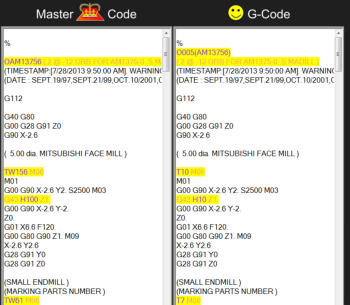

The TWig set-up method uses only an

electronic set-up-sheet instead of your paper

version and is the commonly used method.

The machining G-code can be stored

anywhere in the system and is not required for

the set-up process.

In a “Tool Room” application your programmer

can deploy the job-tools, keeping the whole

programming, job planning and tooling process

under his control, freeing up personnel.

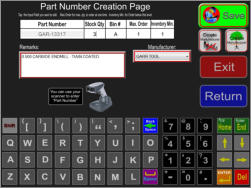

Track your consumables

Inventory tracking.

Automatic re-order list by vendor.

Purchase order tracking.

Bin location sorting.

Know which consumable belongs to which tool.

Send work order automatically to purchasing.

( choose from 3 consumable UI’s)

Why pay a fortune for a tool management system

that has less features then “Tool Wall” ?

Most tool management systems will charge you $ 20 000 plus for a basic tool data

management module. Include a Shop and Consumable module and it will cost you a

lot more. And don’t forget the annual maintenance fee for each seat!

Tool Wall is an all inclusive software that is included, providing you own a Tool Wall

storage system.

If you do not need a new storage system buy the software from us or use it on subscription basis.

You have to update the Tool Wall software once every 12 month. This insures you have always the

latest version and tool manufacturers content. Updates are free.

Or you can buy an “Unlimited” option from us. No time restriction for updates!

Still under development

Still under development